| .Fastening of the switch cable |

| ����The switch bodies are filled with resin for sealing purposes.To acoid stressing |

| ��the cable and switch body,fasten the switch at 5 cm or farther away from the |

| ��switch body,should the wire be bent,the bending radius shall be at least 45mm. |

|

|

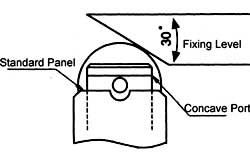

| .Installation |

| ����The service life and accuracy of switches will be effected by the shape of actua- |

| ��tor operation frequency&over travel.So the angular of the fixing level should be |

| ��about 30��,the surface finish of the

fixing level should be over ������ ,the hardness |

| ��is from HV400~500.When installing,the position of the concave part should be |

| ��above the standard panel |

|

| |

��������.Contacttypes |

|

|

|

| |

| .Switch bank mounting |

| ����A maximum of six switches may be mounted together as a switch bank.During |

| ��the installation,the convex part of the switch back.The mounting panel shall be |

| ��6mm or thicker. |

|

| |

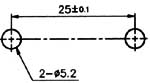

| .Mounting holes |

| ��Mount the switch body to a rigid |

| mounting panel using two M5 |

screws.

|

|

|

| .Mounting |

| ��Reccmmended tightening torque according to the follwing form. |

Model |

Screw type |

Torque |

1 |

M5 fastening screws |

43.4~52lb.in

(50~60kgf.cm) |

2 |

M3.5 installing screws |

6.9~7.9lb.in

(8~9kgf.cm)

|

|

|

| |